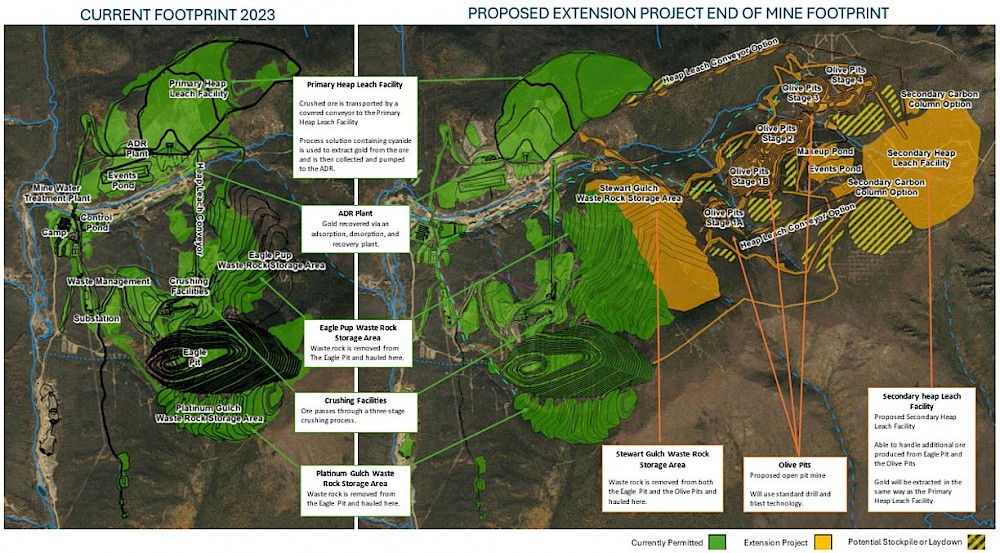

The Extension Project is designed to maximize the use of existing infrastructure at the site. The mine will be able to continue to use the existing and permitted 400-person camp, buildings (e.g., administration and engineering, labs, warehouse) and major infrastructure (crushers, gold recovery plant, mine water treatment plant, trucks, shovels and related mobile equipment) that are already a part of current mine operations.

New infrastructure will be required to support the Extension Project; however, the mine footprint remains within one drainage basin (Dublin Gulch). Activities associated with the Extension Project are:

- The development of the Olive pits; as well as a 10% increase of the Eagle Pit footprint;

- The construction and operation of:

- New second Heap Leach Facility;

- Carbon Columns building at the new Heap Leach Facility;

- Additional fuel storage facilities near the Carbon Columns building;

- Conveyer system between existing conveyor facilities and the Secondary Heap Leach Facility;

- Additional power distribution lines;

- The development of another Waste Rock Storage Area (Stewart Gulch);

- Increase to onsite backup diesel power generation capabilities from 5 MW up to 20 MW;

- Reclamation and closure of new infrastructure.

- Mining Process

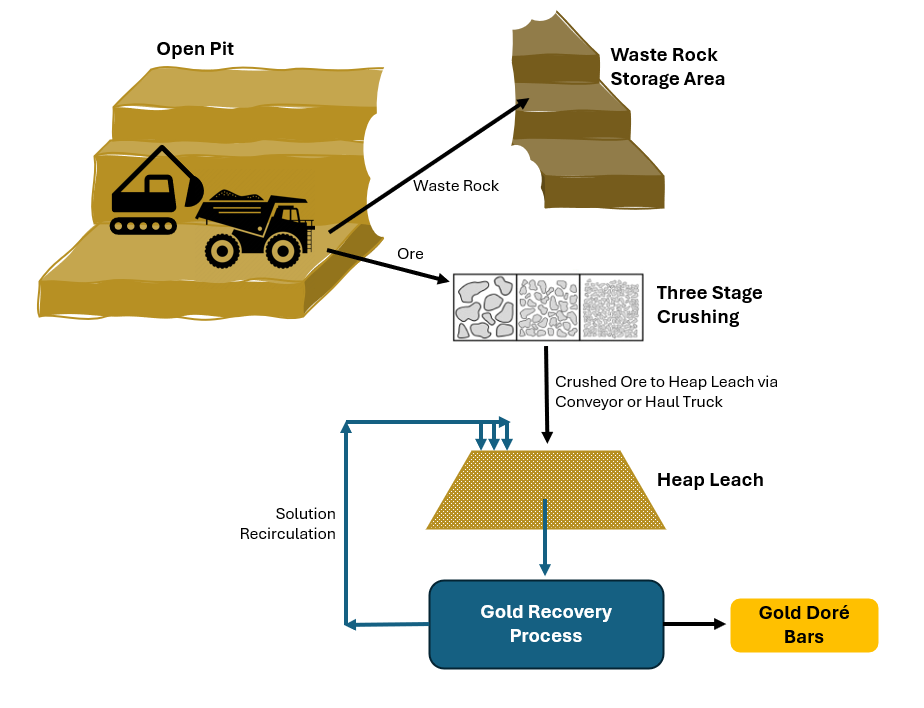

As with the existing Eagle pit, conventional open pit mining methods are proposed for mining ore and waste rock from the Olive pits as part of the Extension Project. The mining process includes drilling, blasting and hauling. Click here to watch video of existing Eagle pit mining operations.

The Olive pits will be developed by drilling and blasting.

Eagle pit Development (July 2023)

Depending on the gold content of the blasted rock, it will be designated as ore or waste rock. Waste rock hauled from Olive pits will be hauled to a new Waste Rock Storage Area (Stewart Gulch). Ore from the Olive pits will either be:

- transported by haul truck to the existing crushing facilities (north side of the Eagle pit) or

- transported by haul truck directly to the new Heap Leach Facility as Run-of-Mine (ROM) ore (i.e., ore that is directly hauled to the HLF from the open pits without crushing) or

- transported by haul truck to a new smaller crushing facility adjacent to the new Heap Leach Facility (alternative being considered).

Over the life of the mine, the Olive pits will advance in four stages, beginning with two starter pits followed by three additional small pits moving successively from west to east.

- Heap Leach

Gold extraction at Eagle Gold mine is achieved through using a three-stage crushing process, heap leaching, and a carbon adsorption, desorption, and recovery system. Click here to watch video of existing Eagle Gold Mine crushing and heap leach stacking operations. Click here to watch video of existing Eagle Gold Mine gold recovery operations.

Ore is crushed prior to placement on a heap leach pad to achieve smaller particle size that is more conducive to extraction of gold from the ore. Depending on rock properties, ore may not require crushing following blasting and may be hauled directly to a heap leach pad (Run of Mine Ore).

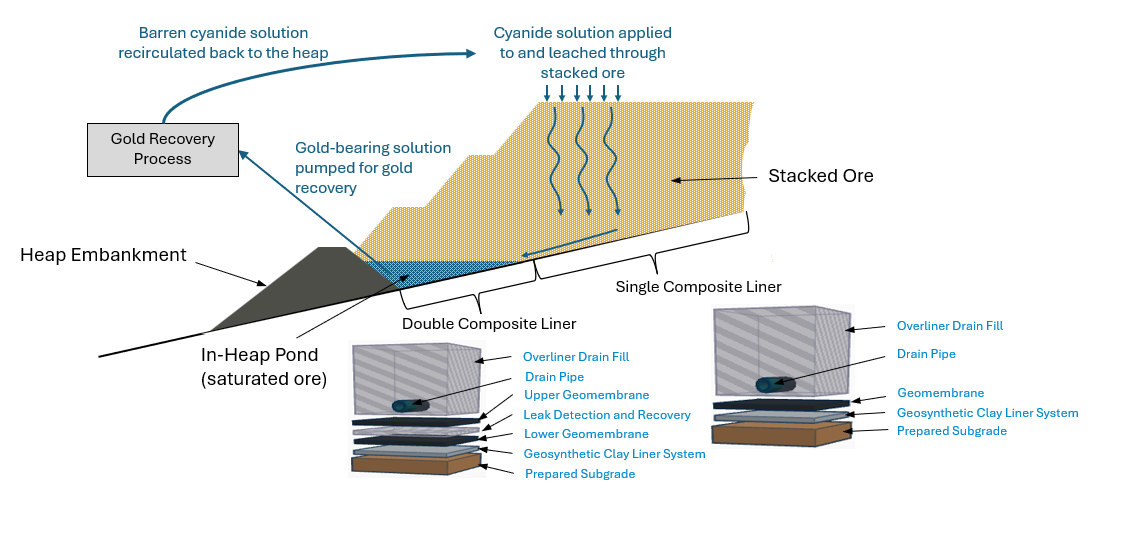

Heap leaching is an industrial mining process used to extract gold from ore. Crushed or blasted ore is stacked on an impermeable liner where it is irrigated with dilute cyanide solution that percolates through the ore. Cyanide is used in gold heap leaching application for its unique chemical properties that dissolve gold from its solid state in the rock into liquid solution. The leach solution containing dissolved gold (referred to as pregnant leach solution) is then collected via a series of pipes to transport solution to the recovery plant where gold is extracted from the solution.

The Extension Project includes construction of a second heap leach facility. Design of this structure is the same as for the existing heap leach facility at the Eagle Gold Mine. The facility consists of a valley fill lined pad that includes construction of embankment in order to create in-heap pond for the pregnant leach solution.

Heap Leach Cross Section

The construction of the new Heap Leach Facility will rely on experience and lessons learned from the construction and operation of the existing Heap Leach Facility and will include quality assurance/quality control programs to ensure design criteria are met.

The photos below show the initial construction of the existing valley fill internal solution storage pond as well as liner installation for initial phase of the pad.

Heap Embankment, Lined In-heap Pond behind Embankment and Liner Deployment on Heap Leach PadSimilar to the current operations at the mine site, at the new Heap Leach Facility, gold-bearing pregnant leach solution will be pumped from the in-heap pond to a new Carbon Column building, where gold in solution will adsorb onto the activated carbon. Loaded carbon will then be transferred to the existing gold recovery plant by tanker truck for further processing to extract gold. Loaded carbon to be transported does not contain cyanide, and all cyanide solution will remain within Heap Leach Facility and Secondary Carbon Column building. At the existing gold recovery plant, gold will then be recovered from the activated carbon through a processes of desorption and recovery. A video of the current gold recovery process can be seen here.

Cyanide use at site is currently, and will be for the Extension Project, be managed under the Cyanide Management Plan. The Cyanide Management Plan has been developed in accordance with the International Cyanide Management Code (ICMC).

- Water Management

Objective: Keep water resources safe and healthy to minimize interaction and impacts to the plants and animals that rely on the water

How:

- Divert clean water as much as possible from Mine areas;

- Capture and manage water that comes in contact with the Mine facilities to be able to discharge water that meets water quality standards; and

- Optimize water use on site to

Process:

Diversion of clean water

- Surface runoff is diverted away from construction and mine operations areas by building stable channels or ponds to catch as much water as possible

- Barriers such as berms maybe be used to redirect water flow

Capture and manage contact water

- Collect contact water in ditches and ponds and recycle back into the process or alternatively, the water may be sent to the existing Mine Water Treatment Plant before it is discharged into the receiving environment (i.e. Haggart Creek).

As part of the Extension Project, more water management facilities will need to be built throughout the life of the project. This includes:

- Adding three new control ponds to allow for storage of water during high flow periods to capture water for later use in the processing activities and to manage flows to Mine Water Treatment Plan. The new control ponds will be similar to the existing control pond.

- Using diversions to redirect non-contact water away from the mine infrastructure, like roads, conveyor systems, and pits.

- Installing culverts to help water flow away from the Mine area.

- Developing ditches to connect existing water management infrastructure to direct flows to Mine Water Treatment Plant, or moving water to the appropriate ponds for storage and if needed subsequent treatment.

- Collecting water in the Olive pits to direct it to ponds for use in processing or treatment.

- Progressive Mine Reclamation

Successful mine reclamation is a priority for Victoria at the Eagle Gold Mine. This means ensuring that the Mine area is restored to viable self-sustaining ecosystems that are compatible with a healthy environment and with human activities.

Progressive reclamation and ongoing reclamation research at the Eagle Gole Mine are being incorporated into the reclamation and closure plan for the Extension Project.

Goal of reclamation and closure:

The goal of reclamation is to restore the surrounding area, both visually and in how it's used, to the extent possible. Ensuring the long-term stability of expanded mine facilities and protecting water quality are key priorities, as well as safety for the public and animals.

What is considered?

- community concerns and priorities

- safeguarding aquatic resources, and

- taking steps to stop invasive plants from growing in the area.

Decomissioning steps:

- Remove structures like the ADR Plant, Secondary Carbon Column building, crushing, and conveyor systems

- Conduct soil and water assessments to check for contamination and remediate as needed

- Demolish and bury remaining foundation structures

- Reshape surfaces for optimal plant growth and drainage

- Replace topsoil and seed with native species to help plant growth, and minimize erosion control

- Regrade waste rock storage areas and place cover material to limit infiltration of precipitation into the waste rock and to promote revegetation

- Regrade heap leach facilities and cover material placed to promote revegetation.

The closure plan also utilizes water treatment in constructed wetland treatment systems. Constructed wetlands are a passive water treatment system that utilizes nature processes found in wetlands to treat water. These systems will be utilized in closure to treat water from pits, waste rock storage areas, and heap leach facilities prior to discharging it to receiving environment. Ongoing research on both cover systems and constructed wetland treatment systems is underway at the Eagle Gold Mine.

Mine Reclamation

- Extension Project Schedule

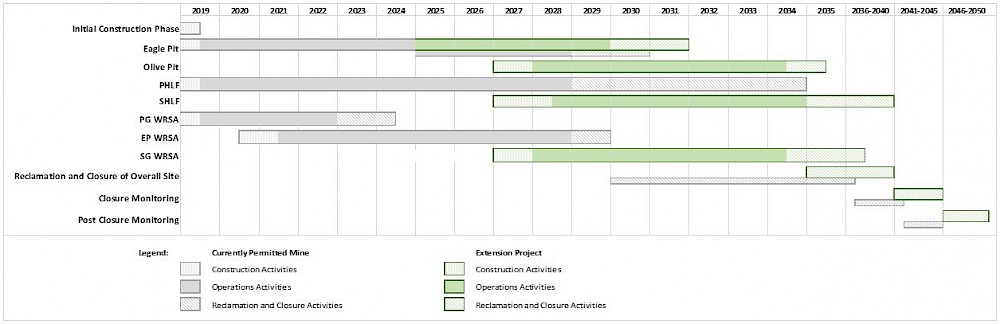

The existing Eagle Gold Mine and proposed Extension Project will include overlapping periods where construction, operation and closure activities occur due to the timing of when certain facilities will be needed.

Olive pits, Secondary Heap Leach Facility, and water management infrastructure will be developed in phases throughout the life of the Extension Project. Over the life of mining the Olive pits, pit development will advance in four phases, from Stage 1 to Stage 4, advancing from Olive Gulch drainage to Bawn Boy Gulch drainage. The Secondary Heap Leach Facility will be developed in four phases, with the footprint expanding over the life of mine. Water management infrastructure will be developed as required to support the expanding mine footprint.

The mine plan for Extension Project focuses on achieving consistent heap leach production rates, mining of higher value material early in the production schedule, as well as balancing grade and strip ratios. Pit optimizations and analyses are continuing to determine the optimal mining shells.

The schedule for Eagle Gold Mine and Extension Project is shown below.